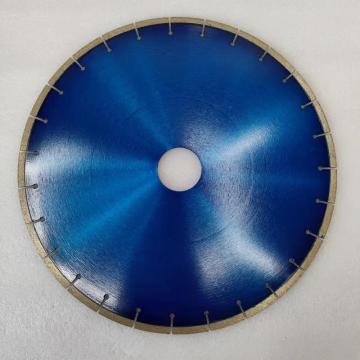

Henan Jinlun superhard material co.ltd is a company that specializes in the production of diamond and CBN (cubic boron nitride) grinding wheels, cutting blades, and grinding heads. With a focus on quality and innovation, the company uses advanced manufacturing techniques and state-of-the-art equipment to ensure that its products meet the highest standards of performance and durability. Whether for use in the automotive, aerospace, or construction industries, Henan Jinlun's grinding wheels and cutting blades are trusted by professionals around the world for their reliability and effectiveness. In addition to its core product lines, the company also offers a range of custom solutions to meet the specific needs of its customers.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.